The Legacy Footprint of Capital

by Ranran Wang and Edgar Hertwich

Manufactured capital assets, such as buildings, machinery, and transport equipment, play a pivotal role in driving economic development and human progress. Yet, a common misconception pins greenhouse gas emissions and resource extractions mainly on short-term consumption. New research published in the Proceedings of the Academy of Sciences (PNAS) shows otherwise, and how the manufacture of long-lived assets continues to intensify global inequities from three critical perspectives —capital access, the environmental burden of this capital accumulation, and economic gains within the global asset supply chains.

Unmasking the Legacy Environmental Footprint (LEF)

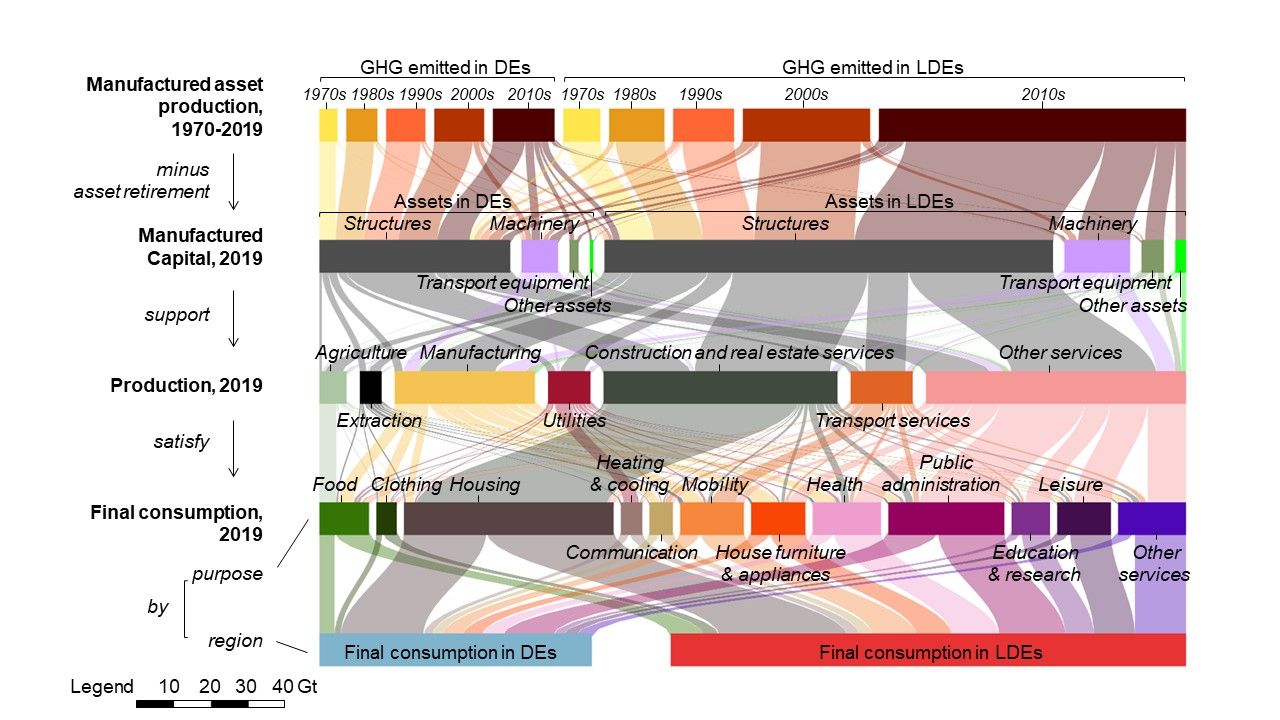

By 2019, global manufactured capital accumulated since 1970 resulted in significant environmental costs. These costs include the emission of 254 GtCO2eq (five times the annual emissions in 2020), as well as the utilization of 31Gt iron ore, 24 Gt copper ore, 507 Gt non-metallic minerals, and 23 Gt wood. Furthermore, the production of these assets cumulatively caused 650 million disability-adjusted life years (DALYs) in adverse health impacts. This legacy environmental footprint reveals the substantial historical costs represented by the capital stock that is used every day to deliver services and produce goods.

The study constructed the LEF pyramids to reveal the dynamics of manufactured capital accumulation across low- to high-income economies. China, in particular, experienced exponential growth in LEF between 1995 and 2019, surpassing the combined LEF growth of Brazil, Russia, India, and South Africa. Developed economies maintained a steady increase in LEF over time, modest in relative terms but larger than the increases LEF per person seen in less-developed economies. Hence, the gap in available capital assets between rich and poor countries is growing.

Tracing LEF from Production to Consumption

Manufactured capital accumulation relies heavily on international supply chains, leading to the outsourcing of environmental pressures and impacts. The study showed that a significant portion of legacy material extractions and human health damages occurred in nations other than those where the capital stocks were accumulated. Developed economies, in particular, had substantial overseas impacts, highlighting a double burden for less-developed economies that provided the raw materials but received a smaller proportion of economic gains.

The study also traced the environmental impacts of manufacturing assets to their use in economic sectors and final consumption. Structures, machinery, and transport equipment were identified as significant contributors to legacy greenhouse gas emissions and human toxicity.

From the consumption perspective, the majority of the global LEF (about 60-70%) is attributable to four purposes: shelter (including housing, heating & cooling, and house furniture and appliances), public administration and security, health, and mobility. Between an average consumer in developed and less-developed economies, the LEF difference is the narrowest for iron ore extraction (133%) and largest for wood extraction (555%). The most significant gaps between developed and less-developed consumers are potentially due to larger floor areas, complex building practices, and generally larger administrative states in developed economies.

The Urgency of Sustainable Investments

As adequate nutrition, sanitation, health care, security, and access to clean water and energy in poorer countries depend on continued investments in manufactured capital, understanding the resource and environmental impacts of this accumulation is crucial. The trade-off involved between the environmental costs of producing capital stocks and the social benefits of the services provided by this capital is a core dilemma for sustainable development.

The LEF per gross value added of production (LEF/GVA) provides a new metric for assessing sustainable investments as it tracks the additional environmental costs incurred by a producer when adding an extra unit of manufactured assets. Unlike flow-based metrics considering direct or indirect impacts in a given year, the LEF-based metric isolates capital environmental efficiency from operational environmental efficiency. The significant variations in LEF/GVA across economic activities highlight addressing resource efficiency, reducing environmental intensities, and promoting circular economy practices can contribute to mitigating the environmental toll of manufactured capital accumulation.

Conclusion

The study's findings underscore the high environmental costs associated with global capital accumulation. The legacy environmental footprint (LEF) provides a comprehensive measure of the historical material extractions and environmental impacts embedded in the current stock of manufactured assets. The research emphasizes the need for policymakers, businesses, and society to consider the long-term environmental consequences of manufactured capital investments. By addressing the resource and environmental challenges associated with manufacturing, we can work towards sustainable development that benefits present and future generations.