How dematerialization could cut hard-to-abate emissions by a third, or more

The production of materials causes a quarter of global greenhouse gas emissions. Reducing the use of materials through a more intense utilization of products such as homes or cars, or the construction of lighter and smaller products, will also reduce the energy needed to provide services such as shelter and transportation.

Dematerialization hence offers two mechanisms by which emissions can be reduced: the use of materials in production and the use of energy in the operation of these products.

In a comparative scenario analysis, we investigated the production, use, and disposal of residential buildings and vehicles in the period up to 2050. We investigated different strategies that could reduce demand for materials that cause high emissions in their production from natural resources, such as steel, concrete, plastics, aluminium, copper, and glass. These scenarios differ in their assumptions regarding future demand for buildings and vehicles, population size, and climate policies.

We focused on residential buildings because they are the most important product of the construction sector, which causes 40% of the material-related carbon emissions. We also chose passenger vehicles because they are the most important consumer product of the manufacturing sector, which also contributes another 40%.

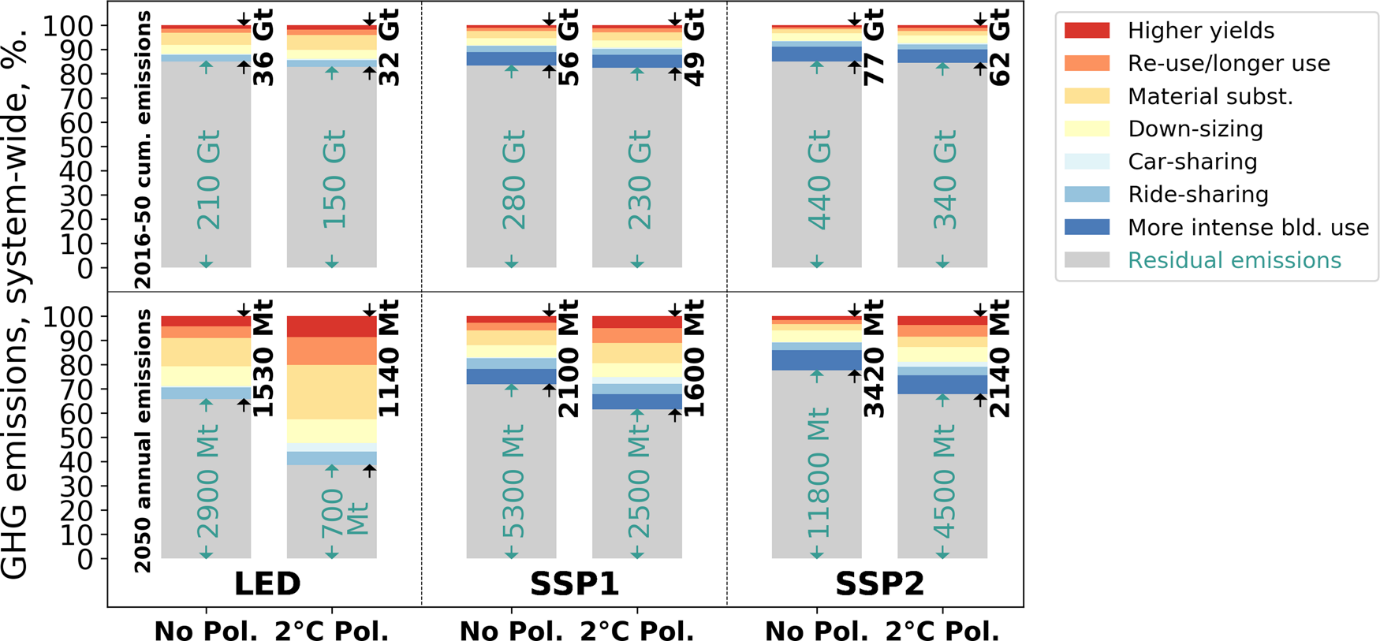

We found that dematerialization could reduce carbon emissions from residential buildings by 20 to 52 Gt CO2-equivalent over the entire period up to 2050, depending on future demand and climate policy. Emissions from cars could be reduced by 13-26 Gt during that period (Figure 1, top row). Full implementation of all strategies is assumed by 2040. In 2050, emissions from buildings and cars would be reduced by one third to two thirds compared to the emissions without the implementation of these strategies.

The modeling demonstrates that material efficiency can deliver savings which are in addition to those that can be achieved through a decarbonization of the energy system, increased energy efficiency, and a rising share of electric vehicles. Figure 1 indicates that, in scenarios with a cleaner energy system and more electric vehicles (2°C policy scenario), the percent-wise reduction of emissions due to material efficiency is higher than in no policy scenarios with a moderate rise of renewables and EVs.

We have investigated ten different strategies to reduce materials use and emissions. For vehicles, there are three strategies which provide most of the reductions. These are quite instructive. The first strategy ride sharing, that is, reducing both the number of cars and the distance driven by riding together. Ride sharing, also called carpooling, is now facilitated by apps such as BlaBalCarand Scoop, which match up people who drive with those who need to go the same direction. Ride sharing is different from ride hailing, in which taxi services are provided to riders independent of the transportation needs of the drivers. Ride hailing does not lead to emissions reductions. Another promising strategy is car sharing, which allows a rental of cars by the hour and close to the place of need. Car sharing can be effective in reducing car ownership, but also serves to shift the trips towards other modes of transportation. The third measure is reducing the size and thus weight of vehicles. This often occurs automatically as a result of car sharing: when you rent cars by the trip, you choose a trip-appropriate car. When you buy a car, you size your car for the most demanding trips you plan, be it a ski vacation, taking the neighbors’ kids to a ball game, or pulling a trailer.

For homes, we assessed that floor space per capita could be reduced by up to 20% compared to the baseline, with a heated floor area in the North of around 30 m2 per capita compared to the current 35 m2in the United Kingdom. Lower floor space not only reduces the amount of building material, but also the energy needed to heat or cool buildings. One measure to reduce floor-space is to have people live in multi-unit dwellings instead of single-family houses. It also reduces operational energy need (because there are fewer outer walls per unit floor space) and increases urban density, which reduces trip distances and increases the attractiveness of public transport and walking/biking over driving.

We also investigated the use of wood instead of concrete and masonry buildings. Timber has much lower greenhouse gas emissions and it binds carbon, both of which helps to reduce the CO2concentration in the atmosphere. We considered that there was only a limited supply of wood. To our amazement, we found that if we combine wooden buildings and floor space limits, total wood demand would not increase, but it would shift from single-family homes to apartment buildings, and from industrialized to developing countries.

Additional measures we also investigated were increased recycling, reuse of parts, increased product lifetime, increased yields of production processes, and the construction of lighter products. All these strategies offer some savings, and overall, the relative savings in terms of materials are larger than the relative savings in terms of carbon emissions over the life cycle of the products. For recycling, there is already a substantial degree of recycling of metals which saves substantial emissions. Expanding the recycling to other materials has lower benefits than the recycling that already occurs.

We also found that product life extensions benefited the climate only when it is applied to efficient buildings and electric vehicles, not to poorer-performing products in the current stock.

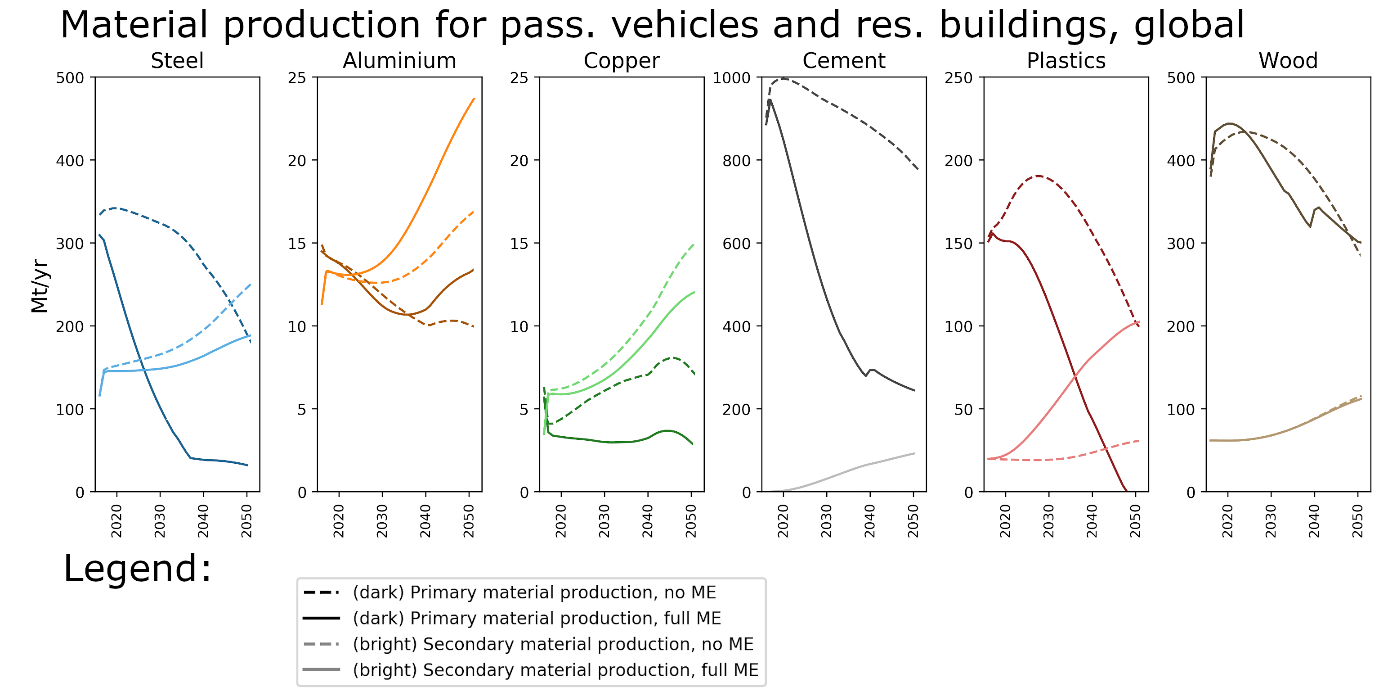

Overall, the strategies we investigated would substantially reduce the demand for material production from natural resources (primary materials) by the two sectors. Primary steel demand would drop to a sixth, cement demand to a quarter, and copper demand to half. The primary materials would, to a substantial degree, be replaced by recycled materials. For the metals investigated, at the global level, secondary production would become more important than primary production within the current decade (Figure 2).

Next to energy efficiency and low-carbon energy supply, material efficiency is the third pillar of deep decarbonization for these sectors. For those promoting the circular economy, this would be a significant development. We would like to note that for achieving this switch-over from primary to secondary supply, reducing the overall demand for materials by reducing the demand for new products is at least as important as increasing recycling rates. It means that if we want to achieve a circular economy, we need to look at more than recycling!

For this research, we built a new model which traces the product vintages, their composition and operational characteristics from production through use and maintenance to the end-of-life where the materials become available for recycling. This model was first applied to the G7 countries in a report for the International Resource Panel, which has informed the formation of the EU’s Circular Economy Action Plan and its Renovation Wave. The new research shows that, in absolute terms, carbon emissions cuts from dematerialization in developing countries are much larger than those in industrialized countries.

Realizing some of these gains is maybe not trivial in terms of policy innovations, but it requires no technical breakthroughs. In fact, the technologies are all in place and we can begin realizing the gains identified in our research quite immediately.